| Items |

50015-01-A

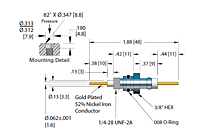

7.5 Ampere (A) Conductor Current Rating and 52 Nickel Iron Pin Tec-Seal™ Pressure Feedthrough

|

50054-02-A

10 Ampere (A) Conductor Current Rating and Cold Rolled Steel Pin Tec-Seal™ Pressure Feedthrough

|

50065-01-A

10 Ampere (A) Conductor Current Rating and Cold Rolled Steel Pin Tec-Seal™ Pressure Feedthrough

|

|

Description

|

N/A

Tec-Seal™ High Pressure Feedthroughs

Tec-Seal™ feedthrough products are built for extreme downhole environments. These rugged hermetic feedthroughs are rated for pressures up to 25,000 psi and temperatures up to 250° C. The Tec-Seal™ embedded seal design will maintain the seal integrity even if one or both sides of the feedthrough are sheared off, thus protecting the bulkhead electronics from damage.

|

|

Direct Current (DC) Voltage Rating

|

N/A

1.5 kV

|

|

Conductor Current Rating Per Pin

|

N/A

7.5 A

|

N/A

10 A

|

N/A

10 A

|

|

Temperature Range

|

N/A

-269 to 250 ºC

|

|

Temperature Range for Viton® O-ring

|

N/A

-25 to 205 ºC

|

|

Pressure at 20 Degree Celsius (ºC) Temperature

|

N/A

25000 psig1724 bar

|

|

Hexagon Size

|

N/A

3/8 in

|

N/A

1/4 in

|

N/A

1/4 in

|

|

Thread Size

|

N/A

1/4-28 in

|

N/A

10-32 in

|

N/A

10-32 in

|

|

Body Material

|

N/A

304 Stainless Steel

|

|

O-Ring Material

|

N/A

Viton®

|

|

Pin Material

|

N/A

52 Nickel Iron

|

N/A

Cold Rolled Steel

|

N/A

Cold Rolled Steel

|

|

Insulation Material

|

N/A

Alumina Ceramic Glass-Ceramic

|

|

Magnetic Material

|

N/A

true

|

|

Additional Information

|

N/A

These standard designs are also built for dual pressure applications, which means that they can take 25,000 psi from either side. These designs are successfully tested to 50,000 psig but the assembly pressure rating is limited by the o-ring. There isn’t a more reliable or durable feedthrough available.

The temperature rating of the assembly is limited by the O-ring material. Viton® is the standard O-ring material used and this material has a high end temperature capability of 205° C. 100% of CeramTec’s Ceramaseal® products are helium leak tested to meet or exceed 10-10 atm-cc/sec (He). Custom bolt sizes, pin configurations or sizes are available upon request.

|

|

Extreme/Custom Design

|

N/A

- Different fittings: cone and thread, NPT, straight thread and weld designs

- Internal pressures from 1 x 10-10 torr to 40,000 psig

- Instrumentation, multipin connector, coaxial, and thermocouple units are available

- Precious metal braze alloys

|

|

Applications

|

N/A

A few of the many applications in which these pressure feedthroughs are commonly used are:- Undersea communications

- Geothermal energy exploration

- Power generation

- Furnaces

|

|

New Products

|

N/A

- Power Plug feedthroughs mounted in NPT fittings

- CeramTite™ glass-ceramic sealed high pressure feedthroughs

- Tec-Seal™ high pressure feedthroughs

|

|

Accessories

|

N/A

Part Number - 0821-01-A

Description - Accepts wire up to 0.062 [1.6]

Material - Nickel Alloy

Type - 0.062 Crimp Contacts

Part Number - 2044-02-A

Description - Accepts wire up to 0.062 [1.6]

Material - Beryllium Copper

Type - 0.062 Crimp Contacts

Part Number - 7332-03-A

Description - Accepts wire up to 0.062 [1.6]

Material - Beryllium Copper

Type - 0.062 Barrel Type Contacts

Part Number - 7429-01-A

Description - Accepts wire up to 0.050 [1.3]

Material - Beryllium Copper

Type - 0.094 Set Screw Type Contacts

Part Number - 7332-04-A

Description - Accepts wire up to 0.094 [2.4]

Material - Beryllium Copper

Type - 0.094 Barrel Type Contacts

Part Number - 2840-05

Description - For 0.025” - 0.075” Crimp Diameters

Type - Crimp Tool

|

|

Features

|

N/A

Accelerators Cryogenics Fusion High Current High Energy Physics High Temperature High Voltage Laser Technology Microwave Nuclear Photovoltaic Semiconductor Equipment Superconductivity Ultra-High Vacuum

|