| Items |

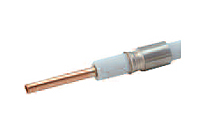

16476-01-W

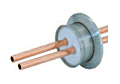

Single Conductor Weld Installation Liquid Cooled Radio Frequency (RF) Power Feedthrough

|

16959-01-KF

Single Conductor International Organization for Standardization (ISO) Flange Installation Liquid Cooled Radio Frequency (RF) Power Feedthrough

|

16941-01-CF

Single Conductor ConFlat Flange Installation Liquid Cooled Radio Frequency (RF) Power Feedthrough

|

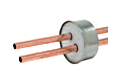

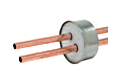

16976-01-W

Dual Conductor Weld Installation Liquid Cooled Radio Frequency (RF) Power Feedthrough

|

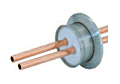

17119-01-KF

Dual Conductor International Organization for Standardization (ISO) Flange Installation Liquid Cooled Radio Frequency (RF) Power Feedthrough

|

|

Description

|

N/A

An assembly which provides for the transfer of electrical power, gases or fluids from outside a hermetic chamber to the inside. Feedthroughs can provide both a hermetic seal and electrical isolation from the chamber wall. Feedthroughs are sometimes referred to as 'pass-throughs'.

CeramTec feedthroughs provide the solutions for applications requiring hermeticity and electrical isolation.

|

|

Direct Current (DC) Voltage Rating

|

N/A

14 kV

|

N/A

14 kV

|

N/A

14 kV

|

N/A

8 kV

|

N/A

8 kV

|

|

Conductor Current Rating

|

N/A

100 A

|

N/A

100 A

|

N/A

100 A

|

N/A

|

N/A

|

|

Conductor Current Rating at 100 Kilohertz (KHz) Frequency

|

N/A

|

N/A

|

N/A

|

N/A

300 A

|

N/A

300 A

|

|

Conductor Current Rating at 300 Kilohertz (KHz) Frequency

|

N/A

|

N/A

|

N/A

|

N/A

250 A

|

N/A

250 A

|

|

Conductor Current Rating at 450 Kilohertz (KHz) Frequency

|

N/A

|

N/A

|

N/A

|

N/A

200 A

|

N/A

200 A

|

|

Conductor Current Rating at 13.56 Megahertz (MHz) Frequency

|

N/A

100 A

|

|

Pressure at 20 Degree Celsius (ºC) Temperature

|

N/A

500 psig35 bar

|

N/A

|

N/A

500 psig35 bar

|

N/A

125 psig8.6 bar

|

N/A

|

|

Number of Conductors

|

N/A

1

|

N/A

1

|

N/A

1

|

N/A

2

|

N/A

2

|

|

Temperature Range

|

N/A

-55 to 350 ºC

|

N/A

-25 to 205 ºC

|

N/A

-55 to 350 ºC

|

N/A

-55 to 350 ºC

|

N/A

-25 to 205 ºC

|

|

Installation

|

N/A

Weld

|

N/A

International Organization for Standardization (ISO) Flange

|

N/A

ConFlat Flange

|

N/A

Weld

|

N/A

International Organization for Standardization (ISO) Flange

|

|

Installation Size

|

N/A

|

N/A

NW25KF

|

N/A

NW35CF

|

N/A

|

N/A

NW25KF

|

|

Flange Size

|

N/A

|

N/A

|

N/A

2-3/4 in

|

N/A

|

N/A

|

|

Welding Type

|

N/A

Electron Beam (E-Beam) Welding Laser Welding Pulse-Tungsten Inert Gas (TIG) Welding Tungsten Inert Gas (TIG) Welding

|

N/A

|

N/A

|

N/A

Electron Beam (E-Beam) Welding Laser Welding Pulse-Tungsten Inert Gas (TIG) Welding Tungsten Inert Gas (TIG) Welding

|

N/A

|

|

Housing Material

|

N/A

304 Stainless Steel

|

|

Conductor Material

|

N/A

Copper Tube

|

|

Insulation Material

|

N/A

Alumina Ceramic

|

|

Magnetic Material

|

N/A

false

|

|

Conductor Frequency

|

N/A

13.56 MHz

|

N/A

13.56 MHz

|

N/A

13.56 MHz

|

N/A

13.56 MHz100 kHz300 kHz450 kHz

|

N/A

13.56 MHz100 kHz300 kHz450 kHz

|

|

Additional Information

|

N/A

In addition to remaining leak-free in high and ultra-high vacuum, many of Ceramaseal® feedthroughs can accommodate:- High temperatures

- Cryogenic temperatures

- High pressure

- Aggressive chemicals

A feedthrough is basically defined by the requirements for installation, insulation, and conductor material. The method of interconnection is flexible and left to the customer’s discretion. A selection of push on contacts can be found in the Accessories section of this catalog.

|

|

Extreme/Custom Design

|

N/A

- Multiple feedthrough flange assemblies

- 940-pin header assembly

- Corona-free designs to 180 kV DC

- Currents in excess of 2,500 Amps

- Pressures to 30,000 psig

|

|

Applications

|

N/A

A few of the many applications in which these feedthroughs are commonly used are:- Semiconductor processing equipment

- Particle accelerators

- Furnaces

- Analytical equipment

- In-vacuum coating

- Satellite instrumentation

- X-ray detection equipment

|

|

New Products

|

N/A

- New high-density, low current feedthroughs

- Micro & Mini HV (high voltage) feedthroughs with mating air side cable assemblies

- 40 & 50 kV feedthroughs with mating air side cable assemblies

- 0.154 & 0.250 Power Plugs for safe high voltage and high current connectivity

|

|

Features

|

N/A

Accelerators Cryogenics Fusion High Current High Energy Physics High Temperature High Voltage Laser Technology Microwave Nuclear Photovoltaic Semiconductor Equipment Superconductivity Ultra-High Vacuum

|